Production

Home > Production

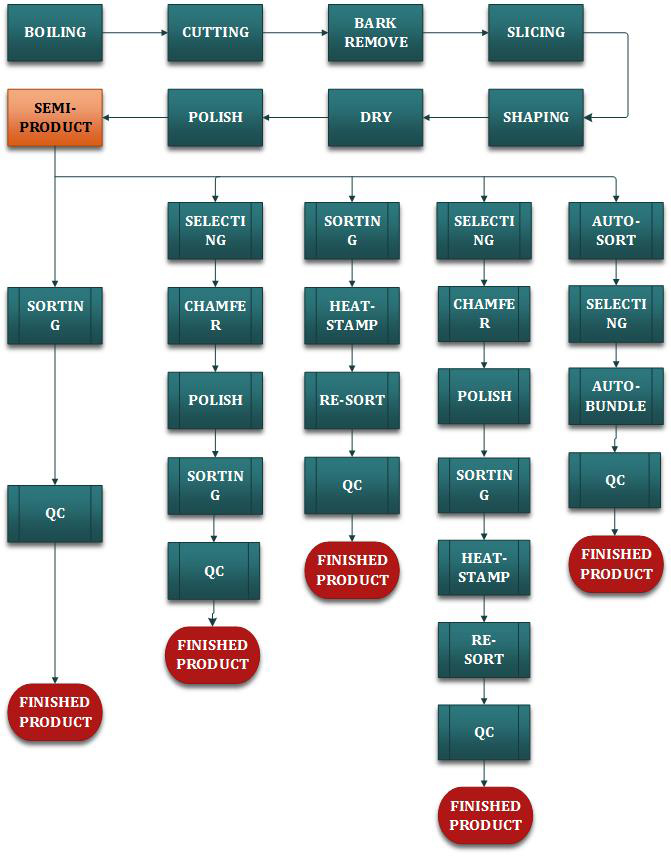

01、Purchasing and Storage: Purchase birch logs from December to June the following year from Europe

02、Soaking:Soaking the logs in heated water in 8 hours for soften.

03、Sawing:According to daily production plan, sawing the timber to required sizes.

04、Bark removing:Remove the bark after sawing

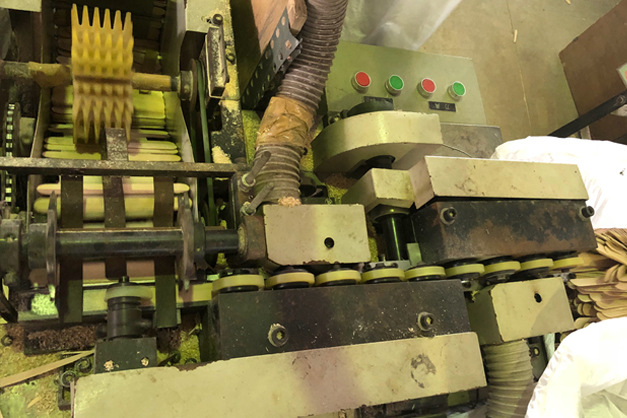

05、Slicing:Slice the wood block to the long strip slice by slicing machine.

06、Punching:Punch the slice strip to required shape by punching machine.

07、Drying and Polishing:Load the semi-products into the huge cylinder for drying over 6 hours in over 100 degree Celsius. Move dry sticks to the roller for polishing.

08、1st sorting:Initial sorting to different grades by sorting machine. (mainly remove waste material)

09、Chamfering (optional):Edge chamfered by chamfering machine.

10、Re-Polishing:Move chamfered sticks to the roller for polishing again.

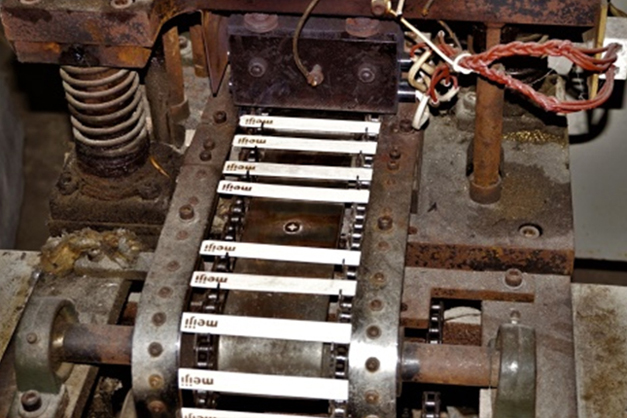

11、2nd sorting:Sort and separate sticks by grades manually.

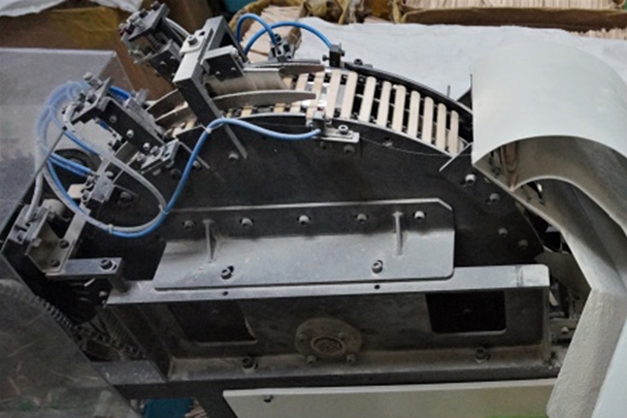

12、Hot-Stamping (optional):Brand the required logo or characters on sticks by hot-stamping machine.

13、Bundling:Keep sticks in order and bundle by paper bundle or manually.

14、Packing (optional):According to the requirements, individual paper wrapping, pack by zipper bag, poly bag or paper box are available.

15、Cartoning:To avoid the moisture, putting a polybag inside the carton before loading sticks into.

16、Storage:Pile the cartons on pallet and store the finished products in the warehouse.

17、QC:Inspecting the final products randomly before shipping. (3% of ordering q'ty)

18、Shipping:Loading the cartons to container and deliver to Haiphong port for shipping.

Hsin Mawh

Hsin Mawh